Purchasing the Right Type of Circular Saw

Why is it important to purchase the right type of circular saw

It is important you get the right type of circular saw blade for the cut or the finish you are trying to achieve.

Before I go any further why should you be taking advice from us.

Ace Saw Services was founded in 1985 by Terry McEvoy. We started from small beginnings in a garage in Drimnagh,Dublin moving on to a modern industrial unit in Churchtown, Dublin 14.

Our job is to advise and supply the correct service or product when it comes to our power tools.

We have extensive experience in all things power tools, particularly when it comes to the correct way to use such powerful pieces of machinery

Why size is important with Circular & Mitre Saw Blades

In the first instance you’ll need to check the bore size of the machine you are on.

This information is usually found in the power machine user manual

The Saw and the bore size need to be the same.

The diameter of the blade is important. Getting this wrong can affect the guard attached to your saw.

Again this should all be laid out clearly in your safety manual documenting the maximum and minimum diameter cuts.

Measure levels should be etched on the blades of the saw

This should be clearly seen as the blade should have notches cut out from the disk. If this is the case then your are dealing with a good quality blade.

Purchasing the correct sizing of blade is important in terms of safety. We will expand on this later in this post.

Different Types of Circular Saw Blades

There are a variety of ways circular saw blades can be used. The design of a circular saw blade also impacts how good a job it does.

This ultimately comes down to the geometry of the teeth.

The way the teeth are constructed and arranged will determine how smooth a cut you get.

In addition to positioning, the blade body must be robust and strong enough to stand up to the various objects and surfaces it will be cutting over its lifetime.

Understanding Blade Construction

Key Features to Consider when purchasing a circular saw blade

- Blade diameter is important as it must match the saw and the type of cuts required.

- Teeth Per Inch (TPI). Blades with a higher TPI provide finer, smoother cuts, while lower TPI blades are better for fast, rough, quick cutting.

- Tooth geometry, including the shape and angle of the teeth, will impact on cutting performance and its suitability for cutting a variety of surfaces.

Maintenance and Safety of circular saw blades.

Never under estimate the importance of the safety and maintenance of your circular saw blades.

You must protect yourself from any accident that could occur using a saw.

Also you will want to extend the life of your product by ensuring it is in good working order.

Regular cleaning to remove resin and pitch build-up, along with sharpening and balancing, ensures the blades perform efficiently.

Proper storage solutions prevent damage and maintains blade integrity.

Along with the safety aspects, you will want to ensure you are wearing appropriate safety gear, including the correct gloves and boots.

Also you want to check you have the saw correctly installed. There should be reference guides with your saw to guide you in this process.

Different Types of Circular Saws

What is a Sidewinder or In-Line Circular Saw.

The Sidewinder Saw is most frequently used in North America. It has an ergonomic design which allows the motor to be on its side.

As the motor is on its right side then the tool can be tilted as opposed to using it on its cut off portion.

Its ergonomic design causes it to be lighter than other similar Circular Saws. Thus it can be used in the overhead position to get a better angle on cuts.

What is a Hypoid Circular saw?

The hypoid circular blade is located to the rear of the motor.

The major difference here is that the hypoid saw has a different setup when it come to its motor gear and transmission configuration

The Hypoid cicular saw get its name from the a hypoid gear, aspiral bevel gear whose axis is not in line with the axis of a meshing gear.

The way hypnoid is designed increases and improves blade contact, which the gives the blade a power but at the same time reduces the motor size and noise.

Also this model has a sealed motor which removes the need for oiling.

Dado Blades

The Dado blade is a unique type of circular saw blade that cuts wide grooves, called dadoes, into wood thus the name Dado blade.

These blades are important in the area of woodworking as they are used to create joints such as rabbets, tenons, and dadoes, that you primarily see in the making of cabinets and creation of shelves.

A dado blade is designed in the following way:

- There are two outer blades interspersed with a series of inner chippers that are flexible enough to be adjusted depending on the width of the cut you are trying to achieve.

- The Main advantage of using these types of blades is the way you can produce wide, flat-cuts in a single pass. This is where they have an advantage over other circular saw blades that cannot achieve this type of cut.

The Dado blade is fully adjustable which makes them flexible to adapt very quickly to project requirements.

The Dado Blade does require greater set up than other blades but they still remin an impressive tool for woodworkers who want to achieve high end quality in their joints when using a circular saw.

Non-Ferrous Metal Blades

These blades have been developed for cutting metals that are not made from iron, such as aluminum, brass, or plastic.

Non-Ferrous Metal Blades blades have a tooth design setup designed to cope with the properties of non-ferrous metals. These metals are softer and more likely to deform on impact than ferrous metals.

The teeth on a non-ferrous blades consist of high-grade carbide. This produces a hardness which allows them to cut through objects cleanly without wearing down as quickly.

There are a number of safety and optimization considerations to be taken into account when using non-ferrous metal blades.

The speed should be set so the blade does not cut too quickly thus creating excessive heat which can lead to blade warping

Also it is vital that the blades are lubricated correctly to guard against friction and heat damage.

Analysing Circular Saw Blade Construction

Material Make up

Circular blades are constructed using high-quality steel alloys, chosen for great strength and resilience.

The steel of the blade is made up of other metals such as tungsten, cobalt, and chromium to strengthen blade durability and resistance.

Blade body

The circular blade’s body is called the plate which consists of a flat metal disc with teeth attached to it.

The body of the circular saw blade is constructed in such a way as to ensure stability and mininse any vibration during cutting.

Key Features to Consider

- Blade Diameter

- Blade thickness will need to vary substantially depending on the job in hand.

- The thinner the blade the less power it will require, whilst a thicker blade used in industrial applications, requires more power.

- Tooth Design

- The shape and design of the teeth can determine what impact it will have on specific materials.

- This concept is also referred to as Tooth Geometry which encompasses shape, angle and spacing of the teeth

Blade Coatings – Extra Protection

The coating of the teeth on a blade is a good way to extend the life of your product.

Overheating can be a problem when cutting through tough materials such as composite decking or plywood. The blade will need protection in this scenario. Thus it is wise to apply coatings

Carbide Coatings

High speeds circular saw blades can soon become worn. Thus most of these blades are carbide tipped.

The carbide allows these blades to be sturdier which allows greater heat and wear resistance.

Carbide is much harder than say steel. In order to sharpen these types of blades special equipment is required.

The teeth of an carbide blade can also be enhanced by coating them in Titanium and Cobalt , which will increase the surface hardiness and minimise teeth wear.

Matching Blades to Materials

Blades for Softwoods

When working with softwoods the higher the tooth count normally the better the cut. In these circumstances you should be looking at a blade with between 40 and 60 teeth

The more teeth on the blade, the smoother the cuts will be

It is also important to choose a blade with a thin Karf as this allows the blade to remove excess waste materials at it cuts into the wood.

This is particularity the case with softwoods as they can be a bit sappy , and a slimmer blade helps cut down on friction buildup.

You should also take into account the blade itself.

Blades with Carbide-tips are a good choice for softer woods because their sharpness remain even after a number of cuts and the blade does not have to be replaced as frequently .

Blades for Hardwoods

A different approach is required for cutting woods like oak or maple.

Here your circular saw blade needs just 24 to 40 teeth.

Less teeth means the cut of the blade can be far more aggressive and go deeper in to tougher woods.

Another thing to take into account is the thickness of the blade. A thicker blade improves stability.

When cutting through thick wood this stability is a crucial factor, particularly when you need a long, steady, accurate cut. This stability will prevent the blade from buckling. Remember there will be more resistance from thicker woods.

Circular Saw Blades for Metals

Slicing through metals like aluminum or steel requires a certain type of circular saw blade. The teeth count for aluminum, is, around 60 to 80.

This type of blade has a triple chip grind (TCG) configuration, which helps deal with the toughness of metal, ensuring a smooth, burr-free cut.

Cutting through other metals like steel requires an even more specialised type of blade. The teeth count on these blades is smaller requiring , around 30 to 50 teeth.

Carbide-tipped teeth are common in blades for plastics as they maintain their sharp edges and resist wear and tear.

Blades for Plastics

When using a circular saw blade on plastics such as acrylic, it is important to be mindful of not cracking or melting the plastic

You should be aim for a blade with a high toot count, say 60 to 80 teeth, in order to ensure the best cut.

You should be looking for a tooth configuration using triple grind (TCG), this way your cuts will be smooth and not damage the delicate plastic.

The blades you use for cutting plastics should be carbide-tipped because of their durability and ability to remain sharp.

The other advantage of carbide-tipped blades is the way they reduce friction, providing a smooth cut.

Maintenance and Care for Circular Saw Blades

Cleaning methods

Consistent cleaning of circular saws is crucial in terms of to extending its lifespan

The first thing you need to do is unplug the blade. Start by unplugging the saw and removing the blade. The safest way to do this is with a wrench

For any persistent dirt or debris use a brush to remove these from all parts of the saw.

Ensure the saw is thoroughly dry and then, wearing gloves at all time, take a cloth to the rust.

Also as the saw will be involved in intensive cuts, check to see if the housing and vents on the saw are clear of dust to stop the saw overheating.

Compressed air is probably the most effective way at cleaning out parts of the saw that are hard to get at.

Also check the power chord lead to ensure there are no cuts or any signs of wear and tear.

Sharpening and balancing

To maintain cutting efficiency its important that you continually sharpen the saw over its lifetime.

The steps

- Secure the blade in a vice

- Begin by securing the blade in a vice and using a saw blade sharpener.

- It is important to sharpen each tooth evenly

- Count the strokes you give the teeth to ensure there is a consistent sharpness in each of the teeth

- Check the blade to ensure there are no imbalances on the blade by using a balancer. This is important as any imbalances in the blade can lead to inaccurate cuts.

- You should build a habit into your routine where you balance and sharpen your blade after a couple of hours of use. This will help you improve efficiency as well as safety.

Proper storage solutions

Storing your circular saw in a safe dry place will help prevent rust. Place the saw onto a hook to prevent any accidental cutting of skin.

As an additional protection you could invest in a saw bag. Saw bags have compartments where blades can be stored protecting it from weather related damage.

The storage area the saw is kept in should remain clear from any debris so as your saw runs efficiently each time it is used.

Safety Gear and Equipment

A safe first approach is very important when dealing with power tools

So what are the items you need. Well firstly you will need a pair of goggles to protect your eyes from the debris that can fly up from the saw.

Next you are going to want to look at getting protection for your ears as power tools and circular saws can be very loud.

Wear gloves to protect your hands from sharp edges and vibrations, but ensure they are snug-fitting to avoid getting caught in the moving parts of machinery.

You will also need to protect your respiratory system by wearing a dusk mask as power tools can generate substantial amounts of dust

Sturdy footwear is also important as power tools can be heavy and you would not want one to injure your feet if something is dropped.

Finally avoid clothing that is too loose as you do not want it to get caught up in a machine.

In your workshop always ensure you have a first aid kit to deal with any minor injuries or cuts

Also, always know where emergency shut-off switches are located for your tools in case you have to switch them off.

Operating Safety Tips

The following are some of the safety tips to apply when dealing with a power tool:

- Familarise yourself with the power manual to ensure you understand how to operate the machine

- Then look over the power tool to ensure you understated all the controls and buttons

- Keep a firm grip on the tool at all times and be aware of of where the tools power chord is so you do not trip over it

- When using the circular saw always work away from the body to minimise the risk of an accident

- Do not use the power tool if you are overly tired or have drunk alcohol.

- Keep children away from your work area

- Unplug the tool when you have finished using it and inspect it regularly in order to extend it lifespan.

Conclusion

Why Buy from Terry McEvoy at Ace Saw Services?

Expertise and Innovation

Founded in 1985, Ace Saw Services, led by Terry McEvoy, brings decades of woodworking and mechanical engineering expertise. We introduced Ireland’s first CNC saw sharpening system, ensuring your blades last longer and perform better.

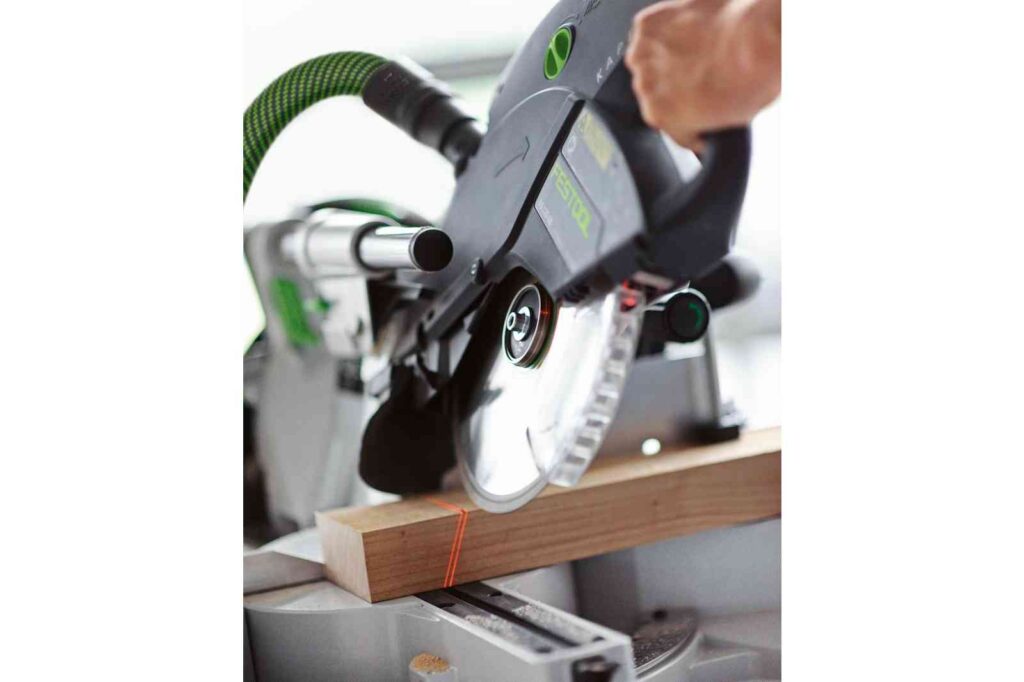

Quality and Precision

We offer a comprehensive range of top-quality tools and accessories, including FESTOOL products. Our precision grinding and custom serrated profile cutters guarantee the perfect tool for your project.

Customer-Focused Service

Our motto, “Service with a smile,” means personalized, respectful service for every customer. We provide tailored solutions, expert advice, and nearly 40 years of experience to tackle even the toughest machining challenges.

Top Brands and Products

We supply only the best tools: Festool, CMT, Titman, Fink, Leut, Fische, Dakin Flathers, First Italy, Rinaldi, and Tigre.

Our commitment to quality ensures top performance for your tools.

Reliable and Friendly Support

Our team is always ready to help, offering friendly, reliable service and problem-solving skills. When you buy from Terry McEvoy at Ace Saw Services, you get a partner dedicated to your success.

Contact us on 086 164 4525 or check our contact page on the website acesawservice.ie/contact

FREQUENTLY ASKED QUESTIONS